810D02 Non Channel Vertical Cavity Surface Emitting Laser (VCSEL) Hair Removal Machine

810D02 Non Channel Vertical Cavity Surface Emitting Laser (VCSEL) Hair Removal Machine

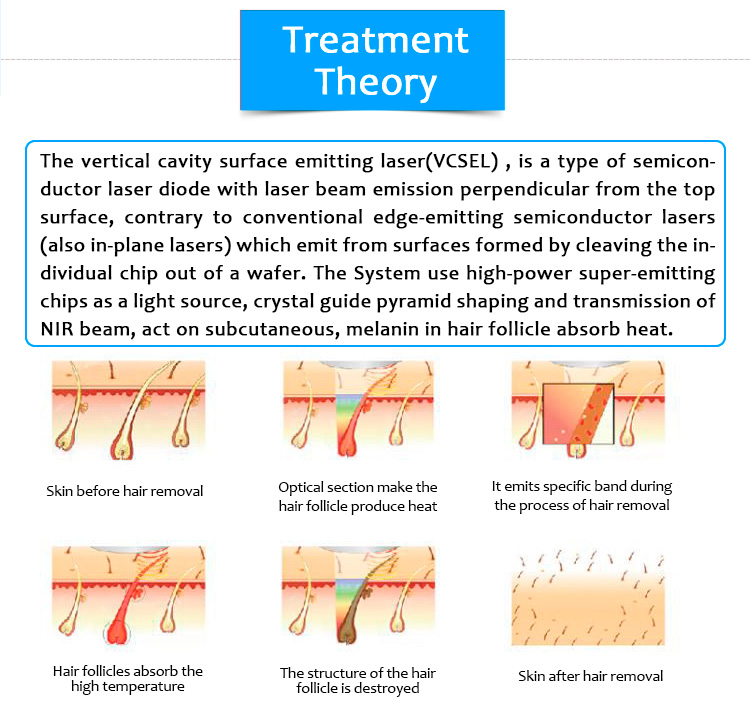

Treatment Theory

The vertical cavity surface emitting laser, or VCSEL , is a type of semiconductor laser diode with laser beam emission perpendicular from the top surface, contrary to conventional edge-emitting semiconductor lasers (also in-plane lasers) which emit from surfaces formed by cleaving the individual chip out of a wafer. The System use high-power super-emitting chips as a light source, crystal guide pyramid shaping and transmission of NIR beam, act on subcutaneous, melanin in hair follicle absorb heat.

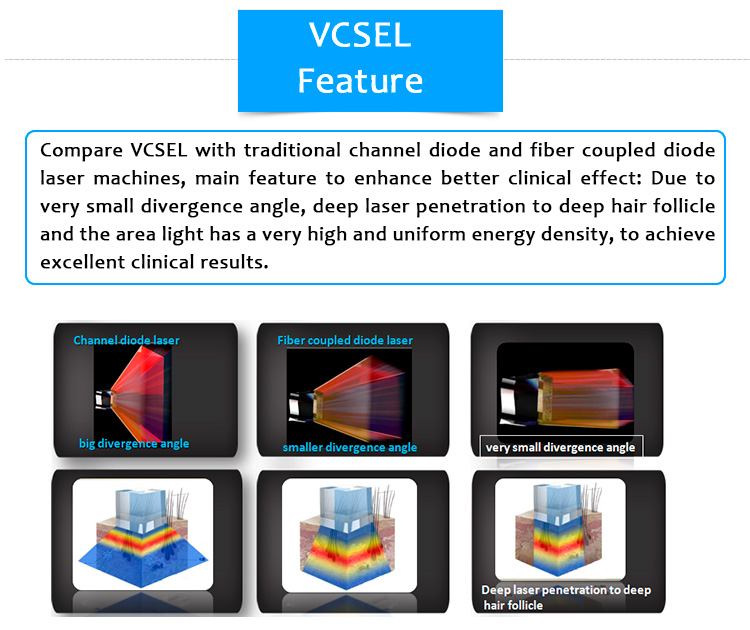

VCSEL Feature

Compare VCSEL with traditional channel diode and fiber coupled diode laser machines, main feature to enhance better clinical effect: Due to very small divergence angle, deep laser penetration to deep hair follicle and the area light has a very high and uniform energy density,to achieve excellent clinical results.

Narrow spectral width &Uniform emission & illumination

3 wavelength: 808nm & 755nm+808nm+1064nm

100 million can reach,3-5 times longer lifetime than channel diode laser

600watt/900watt/1200watt power to enhance clinical effect

Advantages

Beam quality: Narrow spectral width &Uniform emission & illumination

Life Span: 100 million can reach,3-5 times longer lifetime than channel diode laser

3 kinds of power:600watt/900watt/1200watt power to enhance clinical effect

3 kinds of spot size: 12*12mm² / 20*25mm² / 25*31mm² offer for choice. Squared big spot size could prompt the treatment speed, treatment speed and efficiency. Reduce treatment time for original 1/5

3 wavelength: 808nm & 755nm+808nm+1064nm

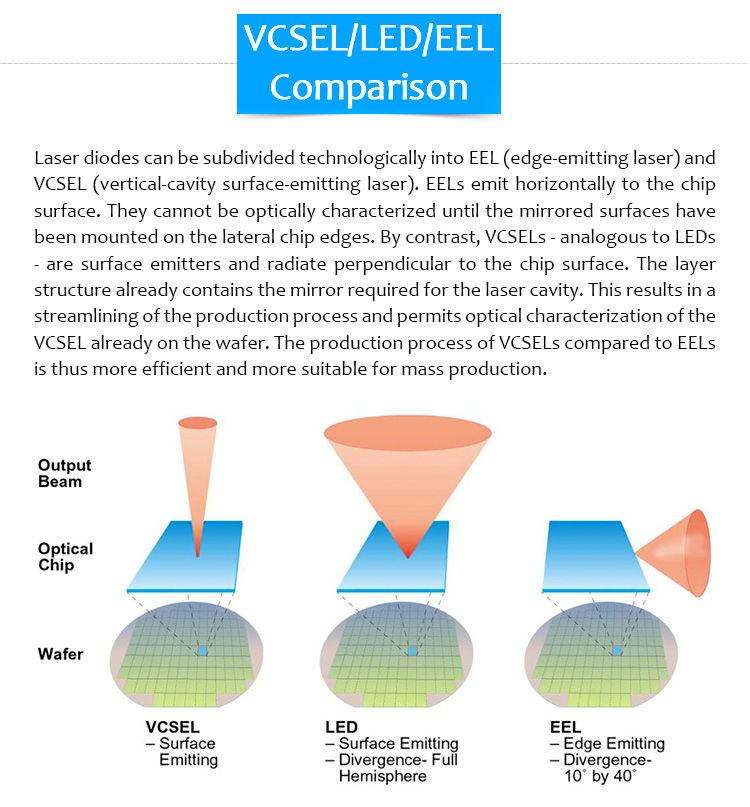

VCSEL/LED/EEL Comparison

Laser diodes can be subdivided technologically into EEL (edge-emitting laser) and VCSEL (vertical-cavity surface-emitting laser). EELs emit horizontally to the chip surface. They cannot be optically characterized until the mirrored surfaces have been mounted on the lateral chip edges. By contrast, VCSELs – analogous to LEDs – are surface emitters and radiate perpendicular to the chip surface. The layer structure already contains the mirror required for the laser cavuty. This results in a streamlining of the production process and permits optical characterization of the VCSEL already on the wafer. The production process of VCSELs compared to EELs is thus more efficient and more suitable for mass production.

| Laser type | Non-channel Vertical cavity surface Emitting Laser hair removal |

| Pulse wavelength | 810nm |

| Chip type | USA bar |

| Laser pulse width | 5-400ms, adjustable |

| Frequency | 1-100J/cm² |

| Display interface | 10.4 inches color touch screen |

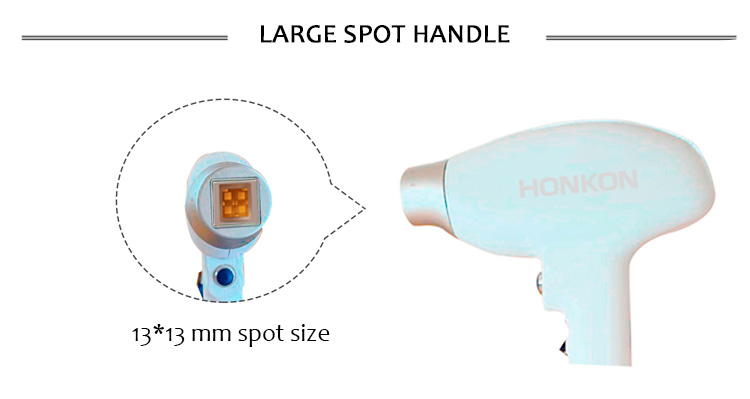

| Spot size | 13*13mm² |

| Output Power | 900W (6pcs chips) |

| Input Power | 2000W |

| Cooling | TEC sapphire contact cooling water cooling |

| Power supply | AC110/220V±10%, 50-60Hz,10A |